In the hands of an experienced metal roof contractor the metal will need to be profiled as a zinc roofing sheet or tray and then by butting together two lengths the raised joints need to be seamed or crimped together using significant force.

Standing seam zinc roof.

This makes standing seam roofs a cost effective solution.

Standing seam is a single folded or double folded seam.

Most types of domestic roofs depending on what materials you use will only last for 20 30 years before they need replacing.

530 mm coil width 600 mm and a metal thickness of 0 7 mm.

The fine lines of the standing seams give the system its light attractive appearance and contribute to its flexibility.

Fixed through to the deck with special fixing clips and screws supplied by vmzinc.

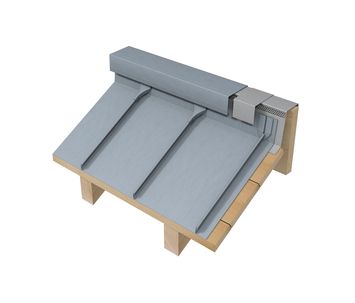

Standing seam cold roof on open gap timber boarding.

We recommend limiting the panel width to 430 mm and the metal thickness to 0 8 mm for mono pitch roofs with overhangs based on practical construction experience.

Standing seam warm roof on plywood bonded to phenolic foam.

The low height of the seams 25 or 32 mm contributes to the modernity lightness and regularity of the roof and facade while highlighting its architectural purpose.

For larger residential structures and routinely on commercial buildings zinc roofing panels or standing seam are used.

Zinc standing seam roof with level changes on a house.

Standing seam roofing is the most popular way of covering a roof in zinc and has been used for over a century.

Standing seam cold roof on vented plywood.

Whereas zinc routinely appears on residential homes as tiles or shingles and falls in in the range of 4 50 to 6 per sq.

With steel scratches in its coating layer will expose the base material to the effects of oxidation and corrosion.

Standing seam roofing and cladding puts any metal under stress.

With zinc it actually self heals.

What makes zinc truly fascinating is its resiliency.

Standing seam warm roof on cellular glass insulation.

All metal roofs including zinc can be scratched.

Standing seam warm roof on rigid insulation.

The double lock standing seam is a further development of the original hollow seam or the simple standing seam.

With this warm roof system zinc plus standing seam can be installed on rigid insulation without ventilating the underside of the zinc plus.

The use of profiling and seaming machines for the closure of longitudinal seam joints significantly reduces installation time.

First mentioned in relevant literature in 1899 it is the preferred choice over other systems for roof pitches starting at approx.

The international standard size for roofs in double standing seam systems is a panel width of approx.

Standing seam warm roof on insulated metal faced panels.

Zinc standing seam panels come in on the upper end of the material costs or 6 to 8 per sq.